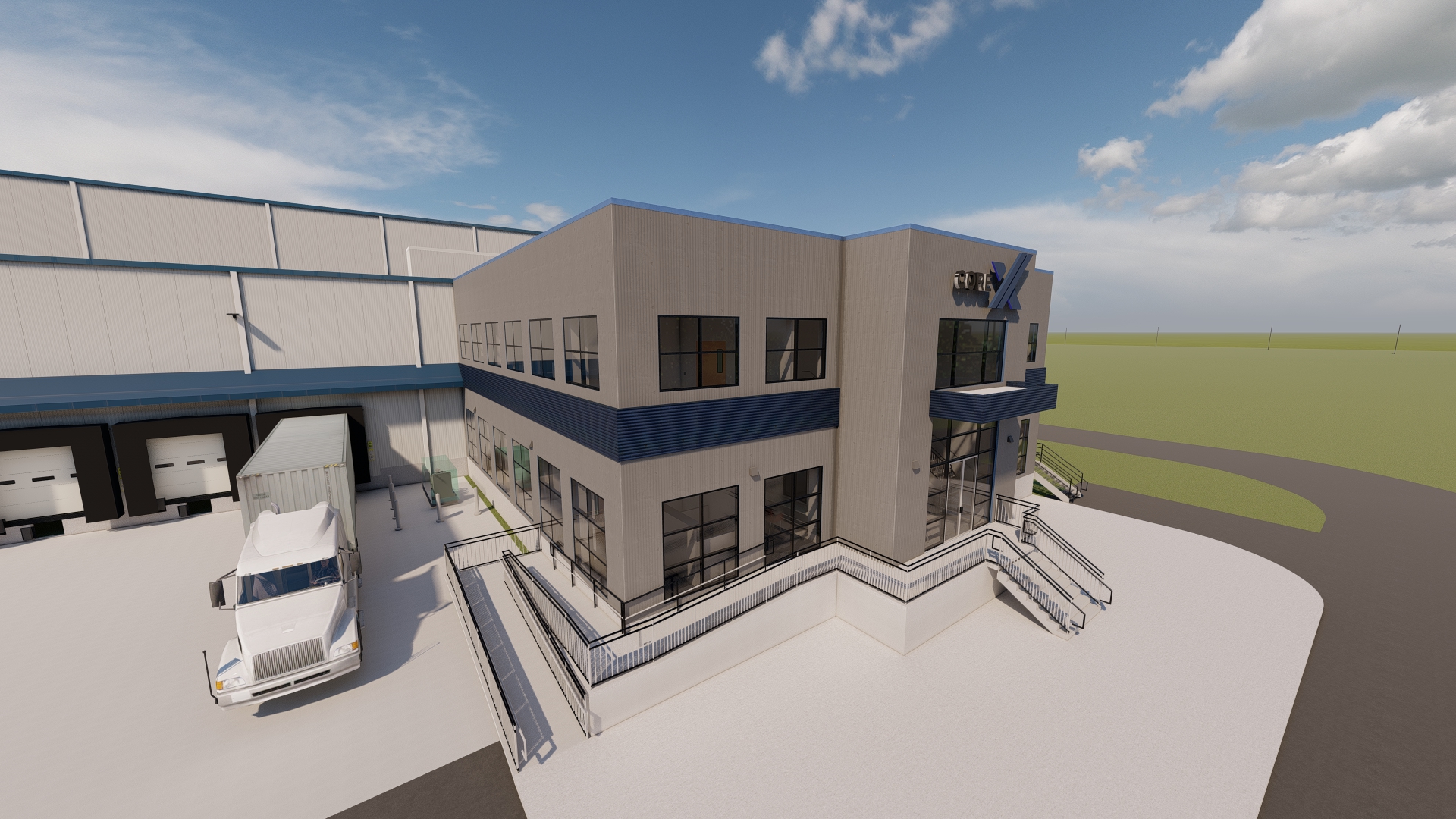

As the latest CORE X Partners development to break ground, CORE X CROWN, in Crown Point, Indiana, will implement cutting-edge pack-n-hold technology within its facility. This advanced technology is set to optimize outbound operations, delivering industry-leading turn times for consolidation and transportation while prioritizing the preservation and quality of stored goods.

How Pack-n-Hold Technology Works

Pack-n-hold technology leverages automated systems to optimize the packing and holding of temperature-sensitive products within cold storage facilities. At the CORE X CROWN facility, this technology will automate the processes of product consolidation and holding at precise temperature-controlled environments. By integrating robotic automation, intelligent storage systems, and advanced temperature monitoring, goods will be packed and securely held in optimal conditions, ensuring their preservation and quality throughout storage.

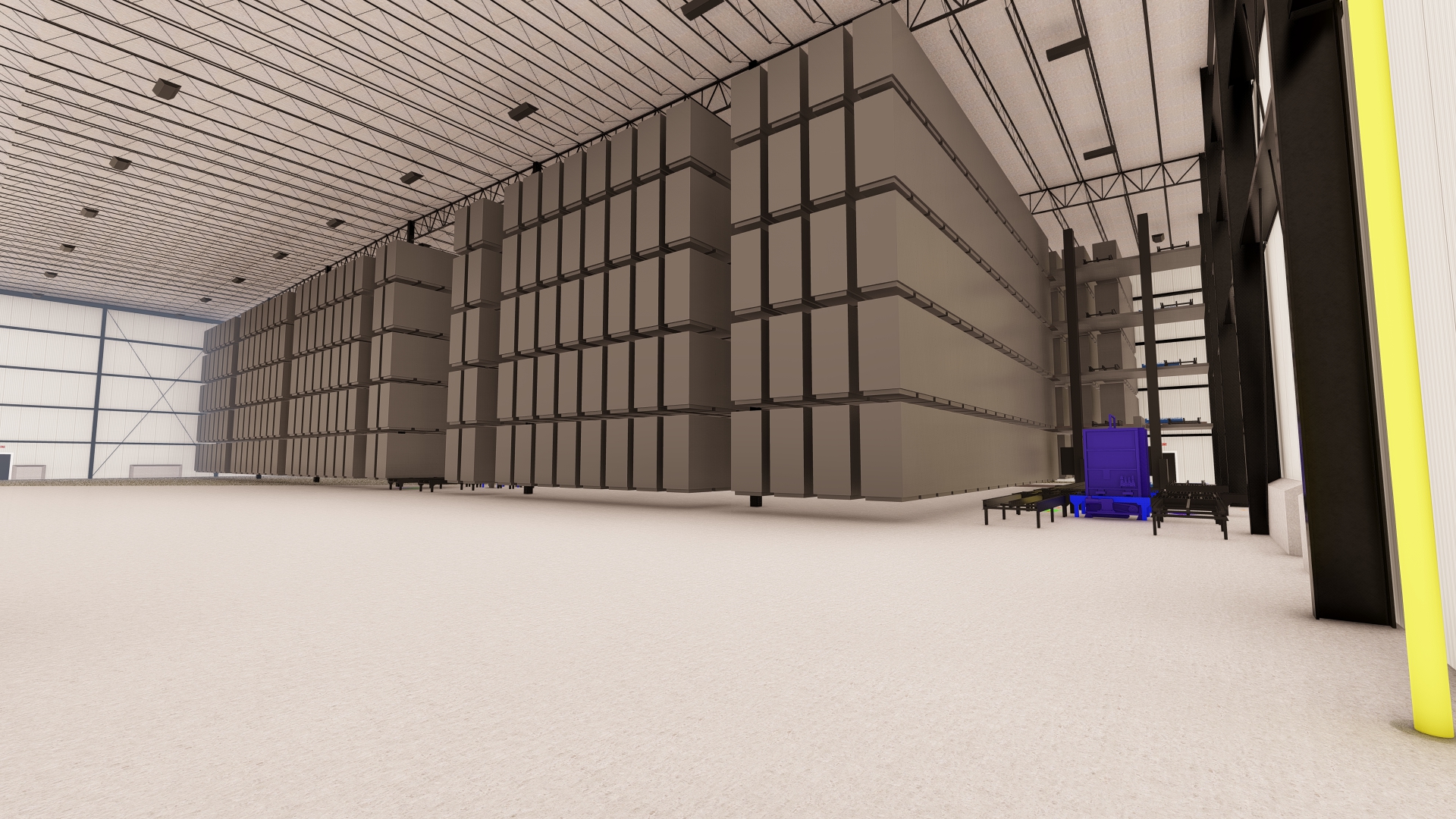

CORE X CROWN will feature a diversified storage racking solution with 16,822 two-deep Frazier selective racking, 6,276 Stow Mobile Racking positions, and 5,311 high-density pallet storage solution using Movu Atlas 2D system for over 28K total storage positions. Innovative, automated features will include:

- Automated Pack and Hold storage solution with Movu Robotics to deliver quick-turn truck loads via pallet conveyor to the loading dock within minutes.

- Mobile racking system that allows for increased pallet density

- Pallet conveyor system for transporting, accumulating, and distributing products

- High-performance layer picking solution for order fulfillment And other elements.

When incorporated into cold warehousing operations, this technology streamlines the packing process, minimizing manual handling and potential errors while maximizing efficiency and throughput. It also facilitates the seamless integration and consolidation of multiple products, optimizing space utilization and enhancing operational productivity. This automated pack-n-hold system will help CORE X CROWN maintain precise control over the storage environment, mitigating the risk of temperature fluctuations and ensuring the quality and safety of stored products.

Benefits of Pack-n-Hold technology

The implementation of pack-n-hold technology at the CORE X CROWN facility provides several benefits for the company and its partners. First, by automating the packing and holding processes, this technology significantly reduces operational downtime and human error, leading to increased efficiency and accuracy in handling products. This, in turn, supports industry-leading outbound times for product consolidation and transportation, enabling CORE X CROWN to provide timely and reliable services to its clients.

The automated nature of pack-n-hold technology also enhances the safety of stored products by reducing their exposure to external factors. It also ensures consistent preservation of the products at the required temperatures, which results in better product quality and longer shelf life. This reinforces CORE X CROWN’s commitment to providing excellent management and storage of temperature-sensitive goods.

Embracing Efficiency, Safety, and Industry-Leading Service

CORE X CROWN’s Crown Point, Indiana facility is proud to feature pack-n-hold technology for increased efficiency and safety. By embracing this advanced technology, the company aims to provide its future partners with unparalleled service capabilities including precise temperature management, accelerated outbound processes, and a steadfast dedication to maintaining the integrity of stored products.